General FlexBind® Printing Guidelines

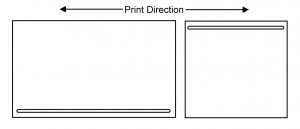

Paper Orientation while Printing

- The hinge should be along either the back or the front of the press while printing to improve toner/ink transfer into the recessed gap. See Illustration.

Feed Drawer Stacking

- Fan stack before loading into the feed drawer. If excessive blocking occurs, verify storage conditions are in compliance with guidelines.

- If possible, assign a drawer to FlexBind® sheets to prevent excessive handling during repetitive loading and unloading between jobs.

- Wedges and stack tilt devices are unnecessary since FlexBind® sheets are perfectly flat and produce no stack bias.

Ream Handling

- Do not flex the hinge before printing

- Do not straighten stacks of FlexBind® sheets by resting the stack on the hinge side of the sheet.

Trimming

- Trimming can be done individually with an in-line trimmer or by stacking multiple books and guillotine cutting the stack.

- The indented laminated hinge allows for stacks of FlexBind® sheets to be cut simultaneously without stack bias.

- Be sure to use a sharp knife to cut the film cleanly without tearing.

- Trim 4 sides of the sheet. Be sure to cut the spine of the FlexBind® page to the proper width for the intended binding method.

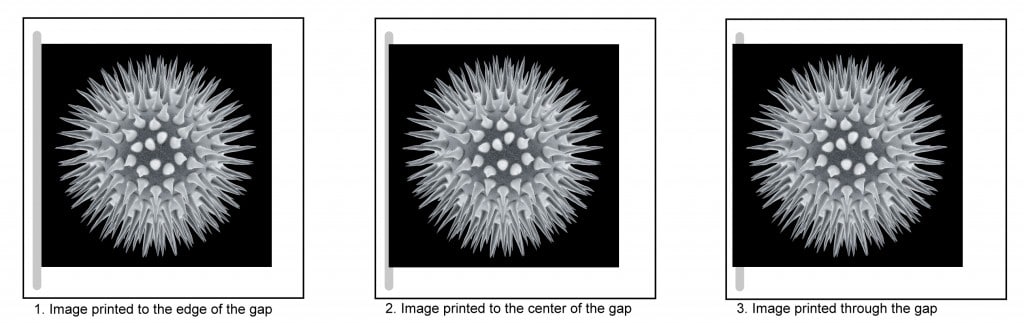

Image position

- Image placement on the FlexBind® sheet should be centered in the hinge gap, or printed over the gap. See illustration.

- If there is difficulty getting toner transfer into the recessed gap, it is recommended to print only to the edge of the gap. (See #1 below)

- Images extending across the binding will need to be individually verified for registration.

- Setup on different paper so as to not waste FlexBind® sheets

- The image should be printed on the laminate as necessary. The laminate is coated to be toner receptive.